When we think of laser technology, where our mind first goes depends on what we think of lasers. Some of us may think of laser cutters, while others think of 3D scanners. There are various uses for lasers, and in this fascinating article, we’ll cover seven uses of laser technology you probably didn’t know about.

What Is Laser Technology?

Before diving into several uses of laser technology, it’s important to cover what this is. To make things simple, you can break the term laser down:

- Light

- Amplification

- Stimulated

- Emission

- Radiation

The laser itself is a small device, but the light it emits is the technological part that various fields utilize.

Keep in mind that not every field uses the same type of laser, as some need higher temperatures for cutting; plus, those used for surgical cutting aren’t the same as the ones used for metal cutting. Additionally, there are different types of lasers: gas, chemical, excimer, solid-state, fiber lasers, photonic crystal, dye lasers, and free-electron lasers. Each laser works slightly differently, and as a result, it best serves a different use.

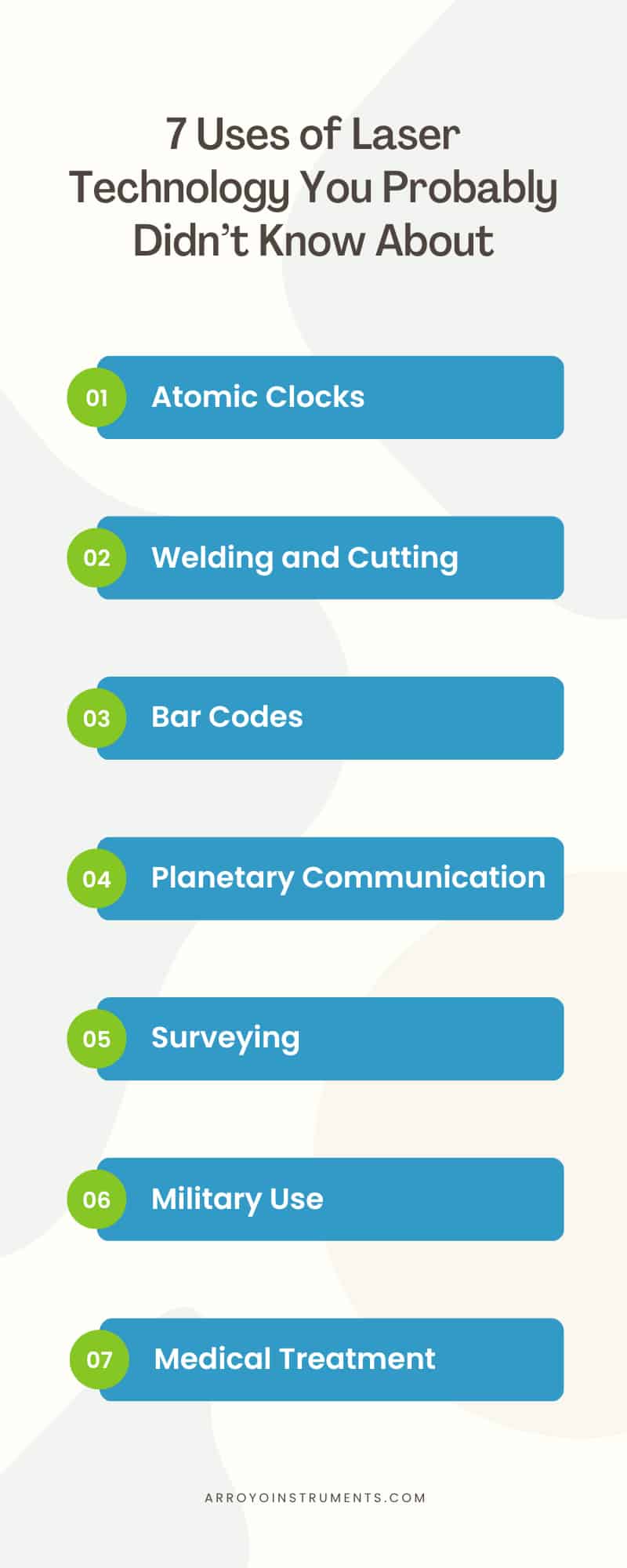

The Uses of Laser Technology

While many engineers use lasers, the list doesn’t end there. Individuals working in industries across the board use a variety of lasers for all sorts of reasons. Some of these uses include:

- Atomic clocks

- Welding and cutting

- Barcode scanners

- Planetary communication

- Surveying

- Military use

- Medical treatment

Each of these relies on lasers for different reasons, but what remains consistent is that this technological advancement has made life more efficient. In fact, you may interact with some of these lasers every day without realizing it. Below, we’ll further expand on how each of these fields utilizes laser technology regularly.

Atomic Clocks

Atomic clocks use atoms to function, and lasers help concentrate these molecules. Some of us use this technology every day without realizing it, as it’s a part of GPS technology. Precision is key here; if the clock is even a few microseconds off, your GPS location could be off by several hundred meters.

NASA also uses atomic clocks to measure the distances between our planet and the spacecraft we send out. And precision is as important here as it is in GPS navigators.

Welding and Cutting

Those working in metal fabrication rely on lasers to cut complex shapes that would be difficult to do with other machinery. These experts also use lasers to apply extreme heat to combine separate pieces into one.

What many may find interesting is that lasers and metal don’t solely come together in the industrial field. Manufacturers also utilize lasers to create essential items like computer chips.

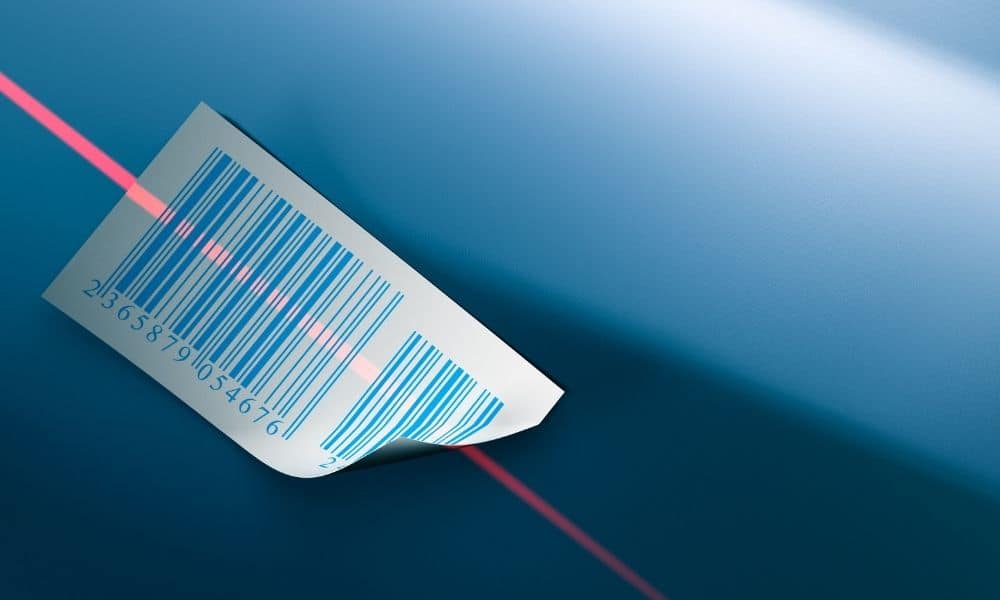

Bar Codes

Lasers even come in handy at the store due to the creation of barcodes and barcode readers. We see these anytime we go to the store. Barcode scanners allow store workers and individuals shipping material to better track inventory. The laser scanner —typically a helium-neon laser— rings up the item’s price according to what’s in the store’s computer system.

Planetary Communication

In 2021, NASA launched the Laser Communications Rely Demonstration, which allows them to test the creation of a planetary internet (Netflix on Mars, anyone?). This is vital to making discoveries in space, as it creates a high bandwidth line of communication between the robots we have in space and scientists on Earth. Thanks to new technology, robotic systems in outer space can communicate with professionals on Earth, which allows for speedy communication and improved data transfers.

Surveying

We can also use lasers to scan a location as we gather information about it. Most impressively, lasers have been used to create detailed 3D scans of entire continents (NASA LVIS) and even other planets (NASA Mars Orbiting Laser Altimeter). This allows us to check an area for features of interest, or to monitor changes in landscapes over time, such as movement of ice sheets or changing topography of desert sands. And with the development of other technology, we can use these scans to create 3D models that allow us to experience any environment without actually being there.

Military Use

While the use of lasers in military applications is well known, perhaps the most interesting is the use of lasers to detect explosives from a safe distance. Using lasers, the actual molecular composition of compounds can be measured and compared against a library of known explosives. By constantly scanning the area ahead, the technology can provide a warning against IEDs and other explosive hazards.

Medical Treatment

The medical field uses lasers for various reasons, including tools needed for cutting and cauterizing. The common medical procedures using lasers are:

- Cosmetics

- Refractive eye surgery

- Dental procedures

- Surgery

While each of these examples falls within the area of medical treatment, they use different types of lasers for a variety of reasons.

Lasers and Cosmetics

During cosmetic surgery, doctors can use lasers to treat the area or for treating conditions like sunspots, scars, wrinkles—and even to remove hair. This is incredibly efficient and ideal for removing anything unwanted from the skin.

Lasers and Eye Surgery

Doctors use lasers for refractive eye surgery because it’s precise, and this allows them to properly reform the cornea, which will help the patient see better.

Dental Work

Dental procedures such as tooth whitening and oral surgery also benefit from laser technology. This is because a laser can make cuts in a hard-to-reach area; it can clean the tooth surface more efficiently when it comes to tooth whitening.

Surgery

We’ve mentioned laser eye surgery and oral care, but general surgeons also make use of this technology in the operating room. The main reason for this is that lasers allow a surgeon to be incredibly precise. Additionally, they don’t need other tools like a scalpel when using a laser for cutting.

Shop for Laser Technology

Now that we’ve discussed the seven uses of laser technology you probably didn’t know about, it may be time to buy the essential equipment for your laser. Laser drivers, temperature controllers, and mounts are all vital components. For example, drivers and temperature controllers prevent your laser from overheating.

Arroyo Instruments

Arroyo Instruments is a laser diode and temperature controller manufacturer that you can count on for high-quality tools. Scientists and engineers have trusted Arroyo Instruments since 2003 for precise instruments needed to use lasers. Plus, we’ve got over 700 custom solutions to ensure every buyer can find the equipment they need for their project. You can get any job done with your laser and achieve the best instruments.