AN-002 – Operating a LaserPak & TECPak as a System

In many cases, it is desirable to use the 585 Series TECPak and 485 Series LaserPak in a system configuration, where the 585 Series TECPak is used to cool a laser diode to the designed temperature, and once temperature equilibrium has been achieved, to turn the laser on.

The essential component of this is the use of the analog interface on the 585 Series TECPak and 485 Series LaserPak. The 585 Series TECPak has a STABLE OUT signal, which will go high once the TEC has achieved stability. This signal can then be used to control the laser on/off state.

For fully autonomous operation, the TECPak can be configured to turn on and stabilize temperature immediately after AC power has been applied, or the operation can be started manually with a signal into the LaserPak.

BASIC AUTONOMOUS OPERATION

For basic autonomous operation, where the TECPak starts automatically and the LaserPak turns on as soon as the TECPak is stabilized, the following steps must be taken:

-

- Adjust the settings for the LaserPak as needed for the application.

- Adjust the settings for the TECPak as needed for the application. See Adjusting the Settings for Stability, below, on how to properly define the stability condition.

- Using the ArroyoUserLimits application, connect to the TECPak and do the following:

- Check the Global Enable checkbox.

- Check the Enable automatic output on checkbox.

- If a delay after AC power on is desirable, enter a delay value, otherwise, enter “0”.

- If you want the controller to always to to a specific set point, regardless of the prior system set point, check the Before turning the output on… checkbox and enter a temperature. Otherwise, ensure that the TECPak has been set to the desired operating temperature.

- Click the Update Protection Settings button and close the application.

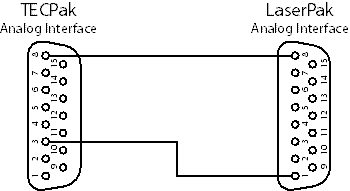

- Create a cable harness using two DB15 Female connector diagram, see wiring diagram below.

- Plus this harness into the Analog Input of each Pak, making sure to match the TECPak end to the TECPak and vice versa.

- Once connected, with the cable made in the step above, the TECPak will turn on once AC power is applied, and once the temperature has stabilized, the LaserPak will turn on.

BASIC AUTONOMOUS OPERATION WITH MANUAL LASER OVERRIDE

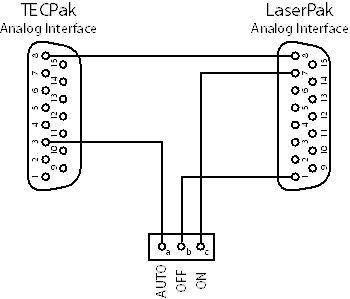

For applications where you would like to have auto or manual control of the LaserPak, but still wish to have the TECPak auto-start, complete the steps above, but replace the wire harness described in step 4 with the wire harness below:

Use a three position switch (connect-open-connect) to connect switch terminals a+b in the AUTO position, terminals b+c in the ON position, and no connections in the OFF (middle) position. In this way, you will be able to control the laser manually, or operate it in automatic mode, based on the position of the switch.

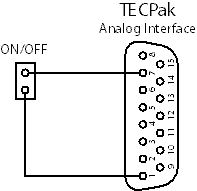

MANUAL TEC OPERATION

If you would prefer to manually operate the TEC, you can combine the switch input harness for the TECPak (diagrammed below) with either of the above harnesses. If you have the automatic output on enabled, the TECPak will turn on on power-up regardless of the ON/OFF switch position. However, when the switch is cycled to the OFF position, the TEC will turn off and you will have manual control. To prevent automatic turn on of the TEC on power-up, you must omit the ArroyoUserLimits setup step (or uncheck the Enable automatic output on).

ADJUST THE SETTINGS FOR STABILITY

A critical step in setting up the system for operation is properly setting the stability criteria. Because the laser is turned on when the TEC is stable, if this criteria is not set properly, the system runs the risk of cycling the laser on and off.

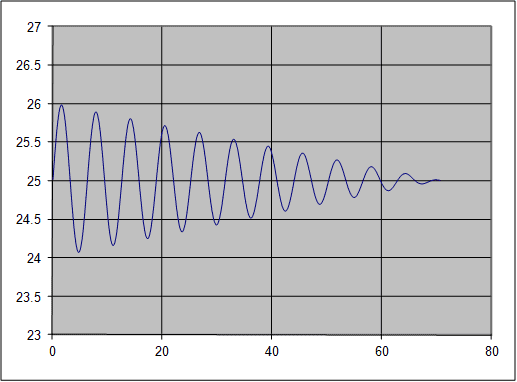

What is stability? It is the point in which the temperature has operated within an allowable tolerance for a specific period of time. Stability is defined as the amount of time the temperature must be within a tolerance of the set point. For example, take the plot of temperature over time as the controller stabilizes at a 25°C set point:

Assume the temperature tolerance is set to 0.5°C, and the time tolerance was set to 20 seconds. The last point at which the temperature was outside of 25°C +/- 0.5°C was at approximately 33 seconds. It is at this point the clock starts tick on the time tolerance. Because the temperature does not exceed 25°C +/- 0.5°C again, at 53 seconds (33 + 20), the output would be considered stable, and the STABLE OUT signal of the TECPak would go high. When connected to the LaserPak, this would then cause the laser output to turn on.

When selecting a tolerance time and temperature, it is important to also consider the impact on stability that the laser will have on the system… when the laser turns on, it will cause the temperature to move in response to the new thermal load of the laser. Your tolerance temperature must be great enough such that the temperature does not move outside of the temperature tolerance specification, otherwise the TEC will no longer be considered stable, the STABLE OUT signal will go low, and the laser will turn off. Because of this, the temperature tolerance often is greater than would normally be used to determine stability, but you can compensate for this be increasing the tolerance time value to a bigger number.

For additional assistance in configuring your system, please contact the factory.