The most critical element of your laser system is your power source: the laser diode driver. Your laser driver will dictate the accuracy, control, and overall performance of your laser application. As you choose the right driver for you, look for these 8 features and ask the laser driver manufacturer specific questions about the function of the instrument you have in mind.

INDEPENDENT ISOLATION FOR CRITICAL COMPONENTS

Your laser is extremely sensitive to being driven beyond its limits. To avoid potential damage from ground loops and other unpredictable factors, your laser diode driver should employ optical or electrical isolation between the user inputs and the driver’s outputs. The areas of your laser driver that should be isolated include:

• Computer interface(s)

• Modulation input

• Photodiode input

ANODE AND CATHODE ARE NOT CONNECTED TO GROUND

Ensure that neither the anode nor the cathode of the laser driver are connected to earth ground. Some manufacturers build their laser drivers this way. An anode-ground or cathode-ground connection can become and problem later for some setups and applications, especially those involving multiple, connected instruments, where the grounding scheme of the laser is dictated by the setup. Avoiding instruments with grounded outputs will allow you the maximum degree of flexibility as you configure your laser system.

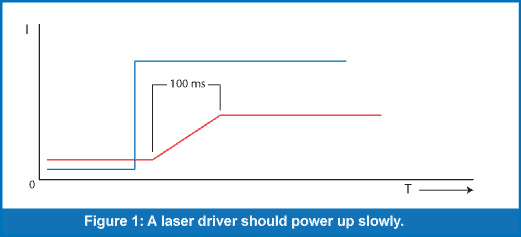

SLOW POWER-ON

When you turn on your laser driver, the system should power up slowly, as shown in Figure 1. This feature is sometimes referred to as soft turn-on. While not required for all application, a soft turn-on minimizes thermal spikes and the stresses they produce. Higher current applications will require longer ramp times. A high current laser diode driver should allow for an adjustable ramp time.

ACCURATE CURRENT CONTROL

A laser’s performance is a direct reflection of the current flowing through the device. As such, consistent and repeatable performance from your laser is only as good as the driver that controls it. Your application will determine the level of set point accuracy, stability, and resolution that you require.

Never use a power supply that operates in voltage mode, as small changes in voltage result in large changes in current, and can easily lead to laser damage. A laser diode is inherently a current-sensitive device, requiring carefully controlled current to function properly.

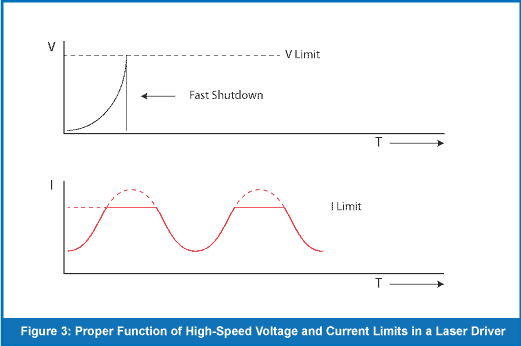

HIGH-SPEED CURRENT & VOLTAGE LIMITS

The voltage limit is a critical piece of the safety system that protects your laser. When the voltage limit is exceeded, your laser driver should power down immediately. In powering down, the laser driver accomplishes two things. First, it protects against excessive voltage. Second, it responds to an open circuit condition before the circuit can be accidentally closed, which would allow a massive current spike.

Not all power sources and laser drivers have a voltage limit, so verify this feature before making a purchase.

In contrast to the voltage limits, the current limit need not power down your system. Instead, your laser diode driver should treat the current limit as a maximum value that it will not exceed. It is especially important to have your current limit set to a reasonable value when you are powering on your laser system for the first time, when you are controlling the laser with a modulated signal, and particularly whenever operating in constant power control (as described in the next point).

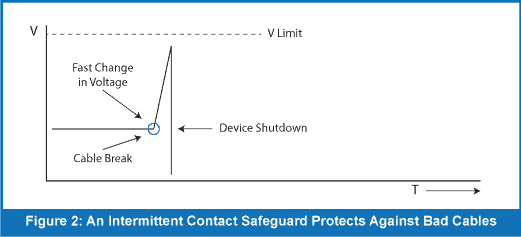

INTERMITTENT CONTACT SAFEGUARD & RATE OF CHANGE DETECTION

An intermittent contact can cause current spikes that will damage your laser diode. This hardware safeguard will power down your laser circuit in the event that a bad cable or some other connector causes an intermittent electrical contact.

While voltage limit protection, as describe above, provides a degree of protection against open circuit conditions, this particular feature measures the rate of voltage change in your system and therefore can trigger a shutdown even more quickly, as shown in Figure 2. When a rapid change is measured, such as when a bad cable quickly toggles its connection, the safeguard triggers a system shutdown and displays an error message.

OPTICAL POWER AS A FEEDBACK SIGNAL

Look for a laser diode driver that allows a photodiode input as a feedback signal. This will expand your laser driver’s utility for a variety of applications. The photodiode measures the optical power produced by your laser. Providing this measurement to the driver as a feedback signal allows you to produce laser light at a consistent power level over extended periods, regardless of the temperature or changes in performance as the laser ages.

WHEN ARE BENCH SUPPLIES APPROPRIATE FOR LASERS?

In any case, careful characterization of your power supply is of the utmost importance to reduce the risk of laser damage. Ultimately, your best option may be to use a laser diode driver. A laser driver will include a variety of safeguards specific to operating a laser. Even the most inexpensive laser driver will offer superior protection, higher accuracy, and better performance than a bench power supply.

LOW NOISE

Because lasers faithfully reproduce the input current, even the noise of the laser diode driver will be reflected in the optical output noise of the laser. Selecting a low-noise laser diode driver will maximize the utility of the driver.

LASER POWER SUPPLY FEATURE CHECKLIST

You can use this easy checklist to verify the laser diode driver you purchase has all of the features you need:

- Optical Isolation for Inputs & Control Circuitry

- Computer connectors (USB, RS-232, GPIB, etc.)

- Modulation input

- Photodiode input

- Free-Floating Anode & Cathode

- Soft Turn-On

- Accurate, Stable Current Control

- High-Speed Voltage Limit

- Intermittent Contact Safeguard

- Current Limiting

- Optical Power Feedback Control

- Low Noise